Interviews and video tours of facilities to help understand what problems exist and explore current workflows

Lenses for the surgical procedures are very costly and sent to clinics on consignment. The current process is incredibly manual and is reliant on the accuracy and planning of a materials manager. In addition, a physical system for billing leads to a long delay in payment. It quickly became clear that a system approach was needed with a strong digital component.

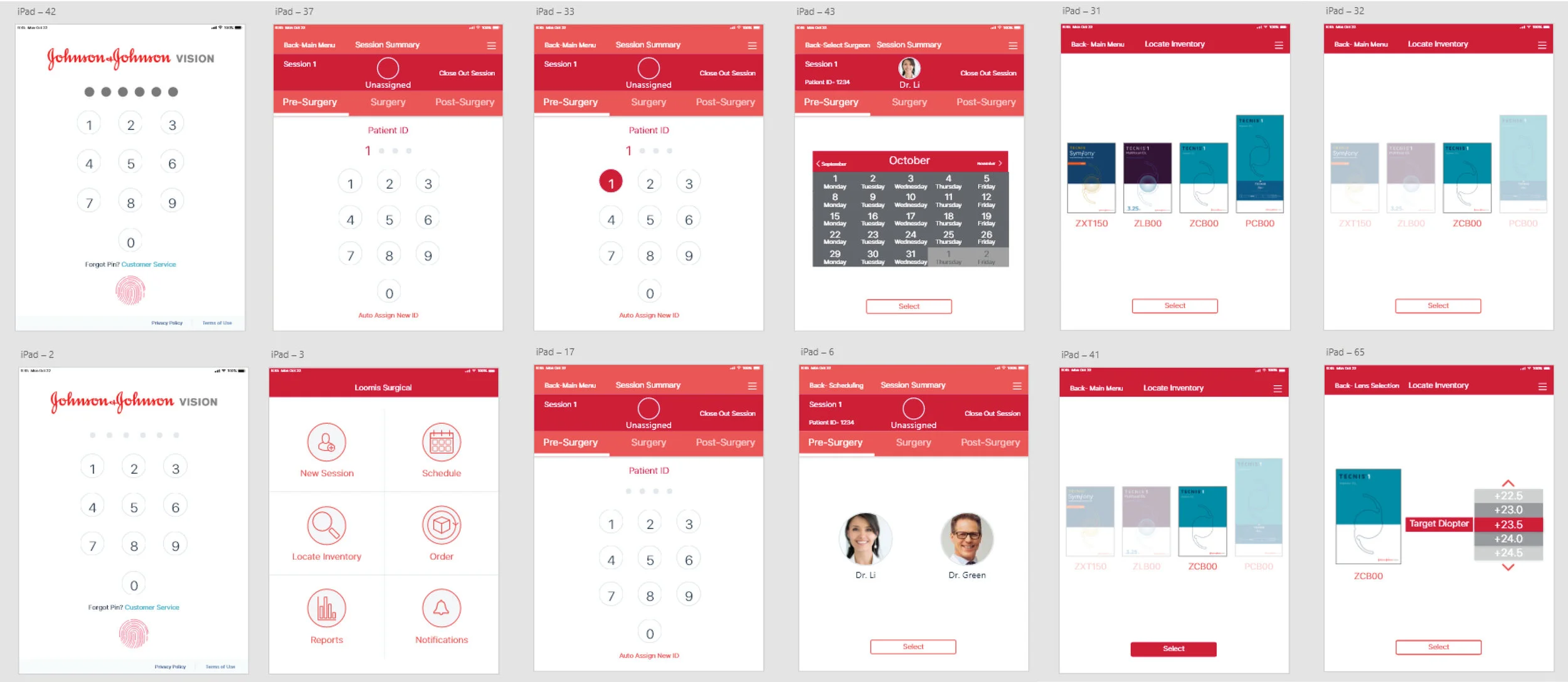

Workflow and App development

An initial concept for a storage cabinet was used in conjunction with a proposed interface. The initial videos (found in the visualization section of the website) helped to explain the new workflow and discover inefficiencies.

Mapping out all of the user scenarios and touchpoints helped indicate pain-points and tasks to optimize. A large part of this was to envision a completely new way of interacting with the inventory. An app with built in scheduling and real time inventory management became the cornerstone of the new experience. Allowing the user to quickly and accurately locate product while ensuring the correct lenses were on hand for every surgery.

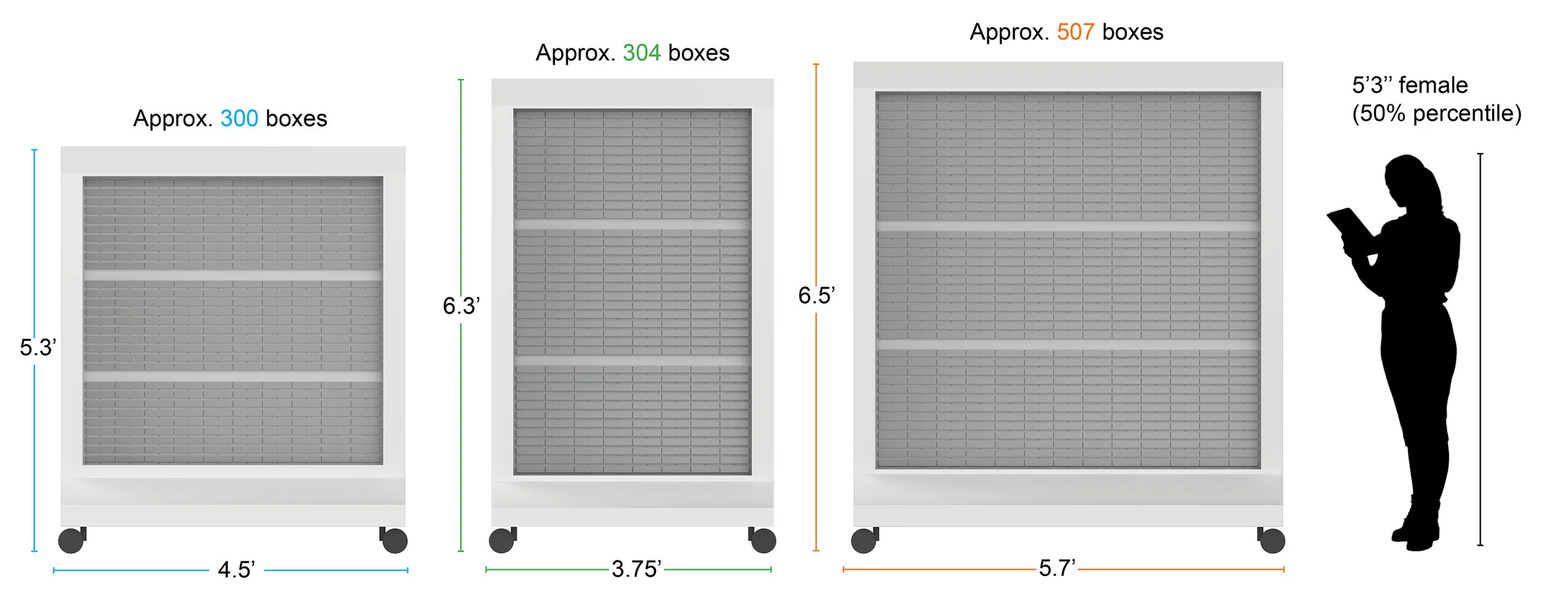

Unit Capacity

The size and capacity of the storage cabinet were key components to the project.

Initial Concepts

Design considerations involved the use of sheet metal construction, LED indicators, Ipad mini integration, and the use of dedicated barcode scanners.

Final Solution:

The mini cable snake became an easy to handle tool with an aggressive look and feel. Private label options were available with a simple color change to the molded parts and label application.

Four prototypes were made for evaluation and field testing of the technology.